Too few LEDs (generally 36 or less) means that they have to be driven at a high current to generate the light output needed. This leads some manufacturers to promote back-lit panels as a low-cost option. What are the problems with cheap back-lit LED panels?īecause they have no LGP it is possible to make back-lit panels relatively cheaply.

Backlit led panel light driver#

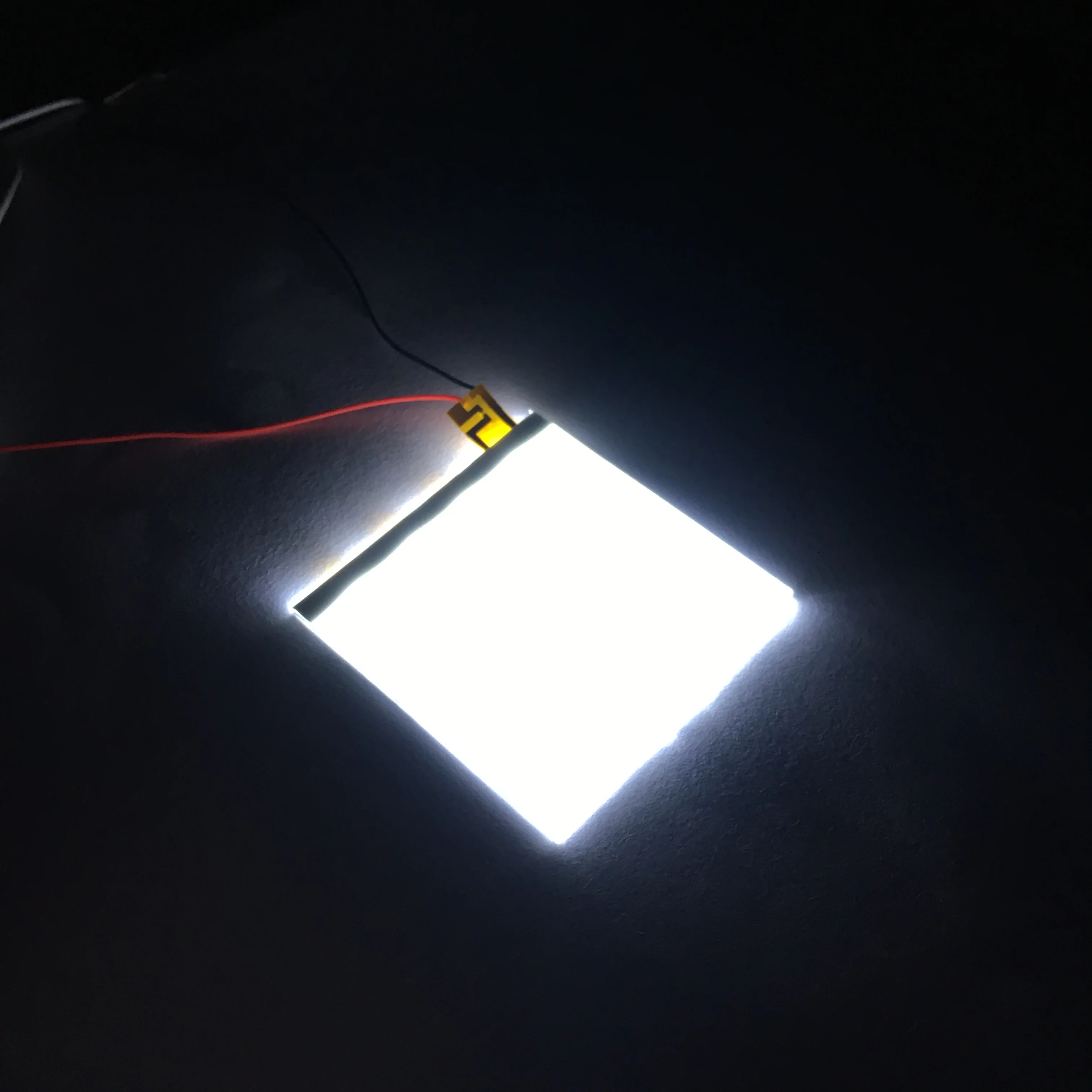

This is because the rear of the panel is the most convenient position for the driver and, because we offer 5 and 7 years warranties, we are keen that the driver should remain as cool as possible. Here at NVC we have had both designs in our product range, but we have decided that edge-lit is marginally better. The lighting market now accepts back-lit panels as readily as edge-lit panels. Because cheaper edge-lit panels used LGPs with a low light transmission, eliminating the LGP altogether, as with a back-lit panel, has meant that back-lit panels have a reputation for being more efficient.Micro-prismatic diffusers have become more common, less expensive and more effective, so the double action of the LGP/diffuser combination is no longer required.Lenses have become cheaper to produce and modern adhesives mean that they can be securely fixed to each LED to create an even light distribution without the risk that they will fall off – a failing with some earlier and cheaper back-lit panels.LEDs have become more efficient, so the thermal advantage inherent in the side-lit design is now reduced, though not eliminated.Technical advances have allowed back-lit LED panels to be introduced. Also, PS has a lower light transmission % than PMMA. Polystyrene (PS) LGPs are now used by some manufacturers, but if UV stabilisers are not added these will yellow with age and the panel will become dull in the centre while the periphery remains bright. In an effort to reduce the cost of edge-lit panels some manufacturers introduced cheaper materials and assembly processes that impacted on their quality.

0 kommentar(er)

0 kommentar(er)